CIFF 2025: The Launchpad for Smart Manufacturing

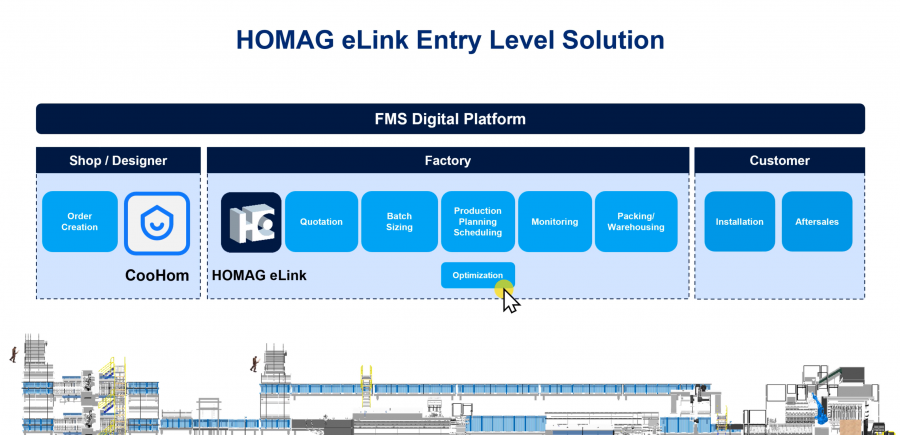

The China International Furniture Fair (CIFF) 2025 in Guangzhou emerged as a pivotal event for the furniture industry, drawing global enterprises and APAC manufacturers eager to adopt smarter production solutions. At the forefront was COOHOM’s collaboration with HOMAG, unveiling E-Link—a digital manufacturing platform designed to empower custom furniture SMEs with speed, precision, and scalability.

E-Link: Redefining Precision from Design to Production

E-Link reimagines the traditional design-to-production workflow by combining intuitive software with advanced manufacturing intelligence. Built on four core values, it addresses the pain points of custom furniture enterprises:

- Ultra-Fast Design: Deliver a what-you-see-is-what-you-get experience, enabling simultaneous design and disassembly to accelerate iterations.

- Seamless Integration: Transition effortlessly from concept to production using a unified catalog system, eliminating fragmented workflows.

- Plug-and-Play Simplicity: Implement E-Link as a cloud-based SaaS solution without costly installations or lengthy training.

- Future-Ready Scalability: Leverage cloud storage to integrate with third-party systems, ensuring adaptability as businesses grow.

E-Link: The Smart Alternative to Legacy CAM Systems

Unlike traditional CAM systems, which rely on manual updates, multiple catalogs, and error-prone validations, E-Link streamlines operations with real-time synchronization. Designers can validate hole and slot specifications directly within Coohom’s interface, while automated model updates ensure consistency across teams. For manufacturers, this means faster approvals, fewer errors, and a 90% material utilization rate—a stark contrast to legacy systems that inflate costs through wasted resources and delayed workflows.

APAC Manufacturers Embrace the E-Link Advantage

The enthusiasm at CIFF 2025 was palpable, with APAC businesses highlighting E-Link’s ability to solve regional challenges like tight margins and complex customization demands. A prime example is Qianwu Furniture, a leading Chinese manufacturer that adopted E-Link early in its implementation. By replacing disjointed CAM tools with E-Link’s unified platform, Qianwu slashed production costs by 20% and reduced time-to-market by 30%. “E-Link transformed our ability to handle intricate designs without sacrificing speed,” shared Qianwu’s production lead. “It’s not just software—it’s a competitive edge.”

Driving Innovation: COOHOM’s Engineering Excellence

E-Link’s technical prowess lies in its ability to tackle complex manufacturing challenges:

- Enhanced Hardware Compatibility: Precision processing of holes, slots, and grooves ensures flawless integration with machinery.

- Collision-Free Manufacturing: AI-driven error detection prevents costly mistakes during production.

- Advanced Processing: Execute specialized tasks like milling, hole-digging, and custom-shaped designs with ease.

- Material Optimization: Intelligent post-processing tools maximize yield through bending and plate-splitting capabilities.

Step into the Future of Custom Furniture Manufacturing with E-Link

Discover how E-Link can revolutionize your workflows:

- Contact us to Schedule a Consultation and Discover E-Link’s Potential

- Connect with us on LinkedIn

- Email our sales team: Sales@coohom.com

The buzz around E-Link at CIFF 2025 wasn’t just about cutting-edge tech; it was about seeing real solutions for the challenges facing custom furniture businesses, especially in the vibrant APAC market. Partnering with HOMAG, we’re not just offering software; we’re empowering manufacturers to build smarter, more efficient operations. If you’re ready to see what E-Link can do for your business, we’d love to show you. Let’s talk about how we can help you step into the future of furniture manufacturing.