For many designer, manufacturers and dealers, the journey from design to production remains fragmented. Design files often stop at the screen, forcing production teams to rebuild data manually. Cutting lists, material quotes, and order forms are recreated across multiple systems—introducing delays, errors, and costly rework.

Every manual handoff increases risk and creates the potential for mismatches between what was designed, what was quoted, and what ultimately reaches the shop floor. The result is longer lead times, material waste, repeated rework, and reduced credibility.

At KBIS 2026, Coohom will showcase how a connected front-and-backend ecosystem changes this reality—seamlessly linking design, quoting, and manufacturing into one continuous workflow.

Coohom: A Seamless Design-to-Production Pipeline

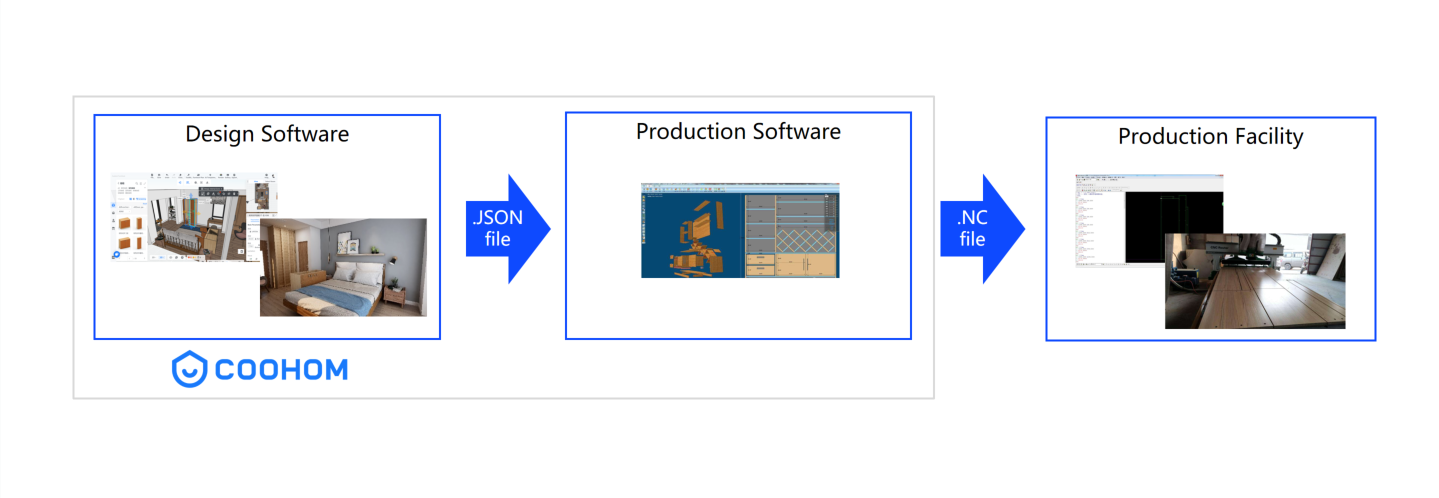

Coohom’s Front & Backend Integration removes these disconnects by turning design outputs into production-ready data. Designs created in Coohom are no longer static visuals. They become structured files that can be exported directly into manufacturing systems—without rebuilding, reinterpreting, or duplicating work.

With this connected ecosystem, teams can automatically generate cutting lists, material quotes & order forms. This unified pipeline enhances accuracy, shortens delivery cycles, and ensures every department works from the same, up-to-date information.

Easily convert design outputs into production-ready files with Coohom.

Easily convert design outputs into production-ready files with Coohom.

Seamless Production Integration, Built for Real Manufacturing

Coohom is compatible with industry-standard manufacturing software, such as Imos, Cabinet Vision, HOMAG and many more, allowing businesses to integrate seamlessly into existing production environments rather than replace them.

By connecting front-end design with back-end manufacturing systems, Coohom replaces fragmented workflows with a streamlined process that supports:

- Faster order confirmation and approval

- Reduced manual data entry

- Greater confidence that what’s designed is exactly what’s produced

From design intent to installation-ready output, every step stays aligned.

Why It Matters: Accuracy at Scale

For manufacturers, this means fewer production errors and less material waste. For dealers and sales teams, it means faster, more reliable quoting and delivery timelines. For designers, it means confidence that their designs will be executed precisely as intended.

Most importantly, it enables businesses to scale operations without sacrificing precision—turning design into a true operational driver rather than a bottleneck.

See How to Connect Design-to-Production Live at KBIS 2026

If you’re looking to reduce errors, shorten production cycles, and build a more resilient design-to-manufacturing process, this is a demo you won‘t want to miss.

Visit Coohom at KBIS 2026

- February 17–19, 2026

- Orange County Convention Center, Orlando

- Booth S29027