Over the past decade, the custom whole-house furnishing industry in Huzhou, Zhejiang province, has flourished. Among them, Zhejiang Mison Smart Home Co., Ltd., established in 2013, has attracted significant attention for its high-quality custom furniture in the industry. However, with the increasingly diverse market demands, Mison faced a series of challenges.

Firstly, the issue of delivery became increasingly prominent, with lengthy order processes failing to meet end-user demands. Secondly, the recruitment and training of order breakdown personnel were challenging, with high error rates and low efficiency becoming bottlenecks for the company’s development. Additionally, the end market demanded higher standards for in-store products, necessitating a continuous expansion of product categories.

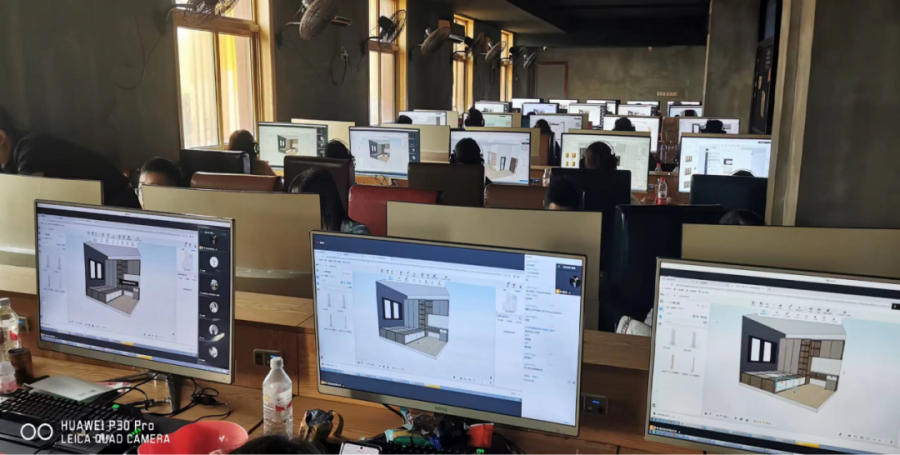

To address these issues, in 2022, Mison chose to collaborate with Coohom, alongside Weilun Technology, to achieve front-end and back-end integration. Through the joint efforts of the three parties, Mison managed to integrate the front-end and back-end within three months, with all dealer terminals successfully switching to and using Coohom’s design software. Over 30 dealers have achieved integrated ordering through Coohom, with an order accuracy rate of 98%-99%. This collaboration provided a reliable solution for smart manufacturing integration without the need to replace the back-end system, ensuring zero-risk implementation. Moreover, it addressed the issues of delivery cycles and human efficiency, offering strong support for Mison’s “Light Luxury Customization” brand strategy.

PART.01

Pioneering Transformation in Whole-House Customization to Seize Market Opportunities

Mison’s General Manager, Hu Dexing, entered the building materials industry in 2001, with a focus on the flooring sector. However, in 2013, after conducting an in-depth market survey, he made a significant decision—to establish the whole-house custom furnishing brand Mison. This decision was not easy, as the transformation will bring about numerous challenges. Nevertheless, Hu Dexing and his team bravely met these challenges and gradually emerged as leaders in the field.

Reflecting on his decision, Hu Dexing said, “Based on my 15 years of experience in the building materials industry and a deep understanding of the sector, along with the current market environment, I decided to establish Mison and fully enter the whole-house customization field. The year 2013 marked the beginning of our exploration into whole-house customization, during which we underwent organizational restructuring and store renovations as part of our strategic transformation. We have very high standards for digitalized production, so we purchased CNC equipment from Germany and implemented the Weilun Technology system, achieving digital management of the production process. This move significantly improved our production efficiency and product quality.” Hu Dexing believes their decision was correct, as the whole-house customization market is currently at an optimal growth phase with huge potential for future development.

To expand its influence, the Mison team actively participated in various exhibitions and franchisee recruitment events, successfully attracting seventy to eighty partners. These partners highly recognized the quality of Mison’s products, further enhancing Mison’s reputation in the market. As a result, Mison secured a place in the competitive market and seized the initiative in the whole-house customization market.

PART.02

Four Major Challenges Emerge, Solutions Found Through Persistent Search

As Mison’s reputation grew and the number of orders increased, a series of new challenges emerged.

- Delivery Cycle Challenge

Due to the cumbersome order process, including design, production, and distribution, the delivery timeline often failed to meet the end customers’ needs.

- Human Efficiency Challenge

With the increase in order volume, Mison faced challenges with the cost of order breakdown and human efficiency. Recruiting suitable order breakdown personnel became difficult, and high error rates and low efficiency negatively impacted the company’s operations and development.

- Backend Software Replacement Challenge

To integrate with the original frontend software, Mison faced the challenge of having to replace its backend software. However, changing the backend software involved technical challenges, could affect the stability of the entire production system, and might lead to production interruptions.

- Product Category Expansion Challenge

As market demands changed, Mison found that a single product category could no longer meet customers’ needs. In addition to traditional panel products, the market demanded more diverse options, such as water-based paints and panel-wood combinations. Mison needed to introduce more design and product options to meet different customers’ preferences and needs, further expanding its market share. The requirement for integration between the frontend and backend systems undoubtedly became higher with the diversification of product categories.

Hu Dexing has always been actively searching for solutions suitable for Mison but remained cautious about existing options. He was concerned about the risks of switching backend systems, as solutions available in the market had not reached a mature level. He recognized that backend issues could have catastrophic impacts. Additionally, he worried that factory technology might not keep up, potentially hindering the implementation of solutions and affecting smooth business operations.

However, during a factory visit in 2022, Hu Dexing discovered the advantages of Coohom’s Smart Manufacturing solution. This solution covers the entire customization process, integrating Coohom with ecosystem partners to simplify implementation through a unified public library, enabling design to order breakdown with zero barriers to integration. This revelation was a game-changer for Hu Dexing, who believed that Coohom’s Smart Manufacturing was a more suitable and feasible solution for Mison.

PART.03

Design and Smart Manufacturing for Mutual Growth: Together, We Usher in a New Era of Mison Integration

In August 2022, Mison, in partnership with Coohom and Weilun Technology, launched the “Integrated Design and Manufacturing” initiative, aiming to further streamline the seamless connection between front-end design and back-end order processing.

In the realm of design marketing, Mison, with the support of Coohom, offers rapid rendering and graphic design services to its end system. End users can harness the Coohom software platform to carry out integrated designs, including customizing cabinets, walls, doors, and combining bespoke elements with ready-made products, based on actual floor plans. Designs can be completed in as little as 10 seconds, and users can also indulge in an immersive experience with one-click rendered animation videos. This enhances the consumer shopping experience, leading to improved order conversion rates and an increase in the average transaction value.

Through the delivery of the “Integrated Design and Manufacturing” project, Mison achieved data interconnectivity between design, order breakdown, ordering, and production, making design-to-order breakdown a reality. The project supports one-click order breakdown, one-click ordering, and one-click generation of construction drawings, effectively reducing production and delivery costs, minimizing error rates, shortening delivery cycles, and easily accommodating various demands.

PART.04

Technology Empowers Business Strength and Sincerely Supports Dealer Growth

Despite the challenges posed by the pandemic, Mison managed to achieve integration and successfully transition the software across all dealer terminal stores within three months. Now, over 30 dealers have smoothly transitioned to integrated ordering with Coohom. This achievement underscores Mison’s strong professional capabilities in strategic planning and execution. Hu Dexing identified four key insights during the project to share and discuss with industry peers.

1.Choose Professional Front-End and Back-End Software

In an era where everything is interconnected, embracing an open, win-win strategy and forging strong partnerships is the optimal approach. Mison chose to integrate with Coohom and Weilun Technology, fully recognizing the importance of professional software. Coohom, as a leading international 3D cloud design platform, offers robust functionality and a user-friendly interface. Meanwhile, Weilun Technology’s order breakdown software, known for its precision and efficiency, smoothens the entire process.

- Unified Vision: Forge Ahead Bravely

In the process of advancing the project, various challenges and difficulties were encountered. Hu Dexing issued a firm directive that, regardless of the difficulties faced, the team should forge ahead bravely without retreating. This belief motivated all employees, enabling the entire Mison team to overcome obstacles and achieve success.

- Organizational Adjustment: Precision Management

To facilitate the project’s implementation, Mison elevated its strategic focus by establishing specialized departments and allocating human and material resources. A dedicated Coohom team was formed under the data center, staffed by three full-time employees responsible for the operation and management of the Coohom project. Through precise organizational adjustments, the project’s progress could be better monitored, and issues could be resolved promptly.

- Front-End Promotion: The Three-Part Dealer Promotion Strategy

To promote the Coohom software, Mison employed an effective promotion strategy, dubbed the “Three-Part Dealer Promotion Strategy.” The strategy includes the following three steps:

- Frequent Online Training

Utilizing online platforms like Tencent Meeting, Mison provides dealers with frequent and convenient video training to help them become familiar with the software’s operations and enhance their skills.

- On-Site Guidance by Dedicated Staff

Mison dispatches dedicated staff for on-site guidance to dealers. When orders or errors are detected in the backend, timely face-to-face, hands-on training and guidance are provided to ensure accurate ordering.

- Designer Incentive Program

An incentive program for designers is established to encourage them to place orders using the Coohom software. Designers are rewarded based on their ordering scores over the year, with different levels of factory price rewards for reaching various score thresholds.

Through these promotion strategies, the usage rate of the Coohom software has been successfully increased, motivating designers to actively use the software and providing them with more rewards and opportunities.

PART.05

“Light Luxury Customization”: Guided by Strategy, Safeguarded by Digital Transformation

Looking to the future, Mison will center its strategy on upgrading to “Light Luxury Customization.” By integrating the functionalities and professional services of platforms like Coohom and Weilun Technology, Mison aims to further enhance the synergy between front-end and back-end operations, reinforcing the advantages of customized home furnishings and industrialized production. This approach will provide flexible design options, rapid delivery, and attentive after-sales service, better meeting consumer demands for personalization, high quality, and convenience in home furnishings.

Contact support@coohom.com to learn more about our solutions.

Social Contact: