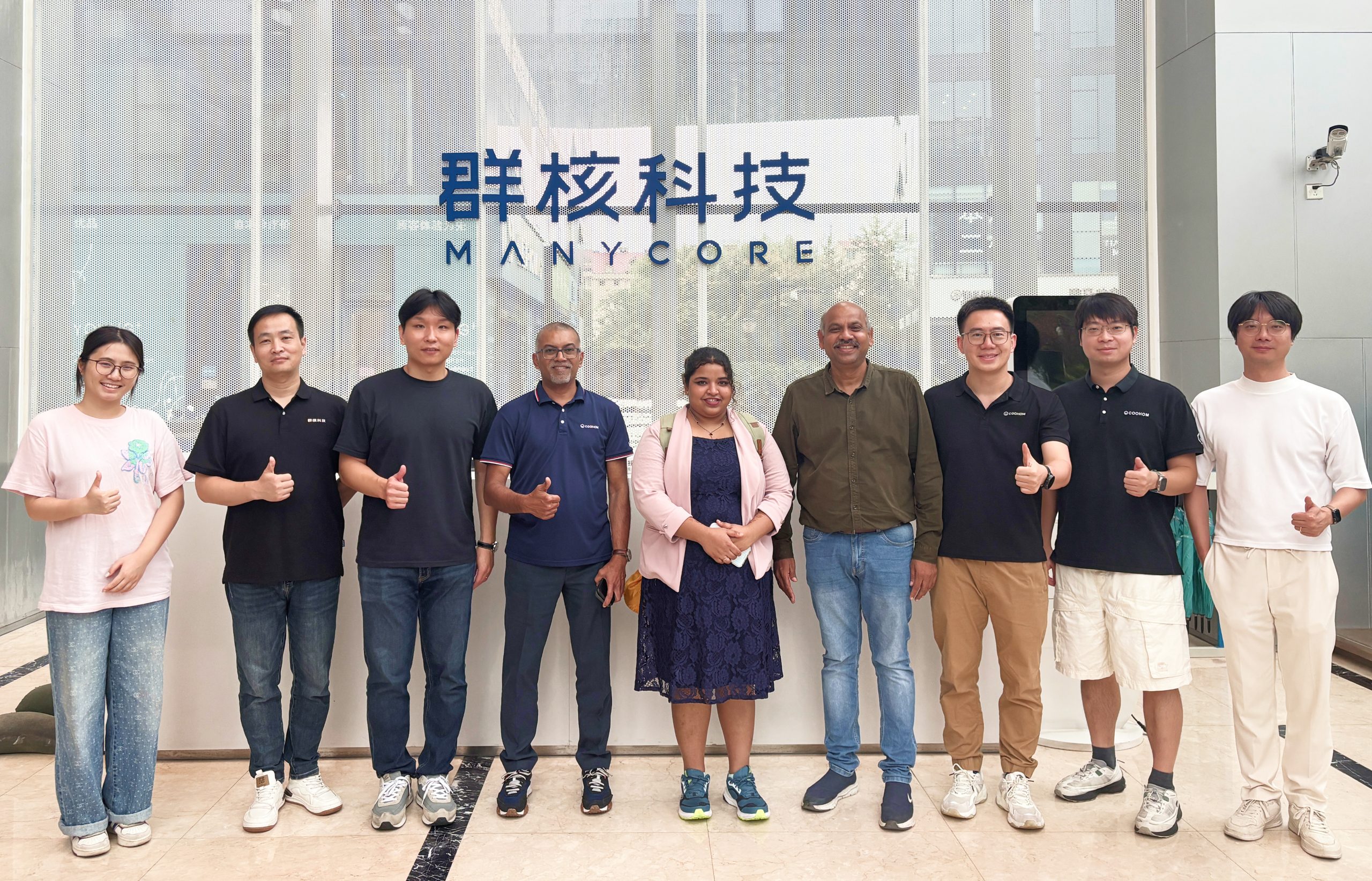

Today, a delegation from Spacewood, one of India’s leading modular furniture manufacturers, visited the headquarters of Manycore Tech Inc., the parent company of Coohom. The visit, which included Spacewood’s Mr. Sridhar and Ms. Soumya, was hosted by Jerry Chen, VP of Manycore Technology and Head of Coohom, and key members of Coohom’s product, sales, and implementation teams. The visit focused on exploring the future of digital transformation for the Indian furniture manufacturing sector.

The session was led by the Coohom product team, who delivered a comprehensive overview of the platform’s powerful visualization capabilities. This included a demonstration of Coohom’s powerful real-time rendering, which allows for interactive design sessions with instant visual feedback, as well as its cloud-based engine for producing final photorealistic assets. The presentations were followed by a live product demonstration and an in-depth Q&A session, providing a firsthand look at the Coohom SmartLink Suite.

For the Spacewood team, the visit proved to be an eye-opening experience, particularly regarding Coohom’s rendering capabilities. The designer, Ms. Soumya, was particularly struck by the real-time rendering, which allowed for instant adjustments to lighting, materials, and models without any lag—a stark contrast to the slow feedback loop of traditional software. She was also deeply impressed by the speed and quality of the final cloud rendering, which generated photorealistic visuals in minutes instead of hours. The ability to output a wide variety of formats, including static images, 720° panoramas, and video animations, was highlighted as a major advantage for creating a full suite of marketing and sales assets. The fact that all this was integrated into a single “render and make” platform was something she had never encountered before, calling the demonstration a truly stunning look at what is possible.

The Vision: An End-to-End Solution for a Nationwide Network

With over 500 dealers and 34 exclusive stores, Spacewood operates on a national scale that demands efficiency and consistency. The key topic of discussion was how a fully integrated digital solution could empower this vast network.

“The pace of change in the Indian market requires us to constantly seek out innovative solutions. Seeing a potential workflow that connects a beautiful 3D design directly to the production line is incredibly compelling. The ability to eliminate data reentry and ensure accuracy from the showroom to the factory would be a revolutionary step for our efficiency and for the customer experience.”

— Mr. Sridhar, Spacewood

The proposed workflow would involve:

- Front-End Design and Visualization: Dealers could use Coohom for all customer-facing design work.

- Seamless Data Handoff: Upon design finalization, the system would generate the technical order data required for manufacturing.

- Automated Production Preparation: This data would include critical instructions like Bills of Materials (BOMs), cutting lists, and technical part descriptions for CNC machinery, ready for integration into Spacewood’s ERP systems.

“We were honored to host an industry leader like Spacewood and share our vision for the future of furniture manufacturing. Our technology is designed to provide a truly connected ecosystem that bridges the critical gap between creative design and precise production. By starting the process in a tool like Coohom, a manufacturer can ensure that the data flowing to their factory is accurate from the very beginning, which is the key to efficiency and quality.”

— Jerry Chen, VP of Manycore Technology and Head of Coohom

Potential Benefits of an Integrated Solution

The discussions highlighted how adopting the Coohom SmartLink Suite could unlock significant business advantages for a manufacturer like Spacewood:

- Accelerated Sales Cycle: By leveraging powerful real-time rendering during live design sessions, dealers can make adjustments instantly, helping customers make confident decisions faster.

- Creation of Rich Marketing and Sales Assets: The ability to quickly generate a variety of high-quality outputs—including static images, 720° panoramas, and video animations—allows for the creation of compelling marketing materials and immersive client presentations.

- Increased Production Efficiency: Delivering machine-ready instructions directly from the design tool could reduce programming time and optimize material usage.

- Elimination of Errors: By automating the transfer of data from design to production, the solution could minimize costly manual errors.

- Enhanced Customer Satisfaction: A more streamlined and accurate process from order to delivery ultimately leads to higher-quality products and greater customer trust.

Today’s visit and productive discussions underscore Spacewood’s forward-thinking approach to innovation. The meeting has laid the groundwork for a potential collaboration that could redefine efficiency in the Indian furniture market and optimize Spacewood’s entire value chain, from initial concept to final product delivery.