A Global Stage for Innovation

LIGNA 2025, held in Hannover, Germany, brought together the world’s leading woodworking and manufacturing innovators. As the industry’s premier event, it was the perfect platform for Coohom to unveil SmartLink Suite — a next-generation digital manufacturing solution tailored for custom furniture producers seeking efficiency, flexibility, and scalability.

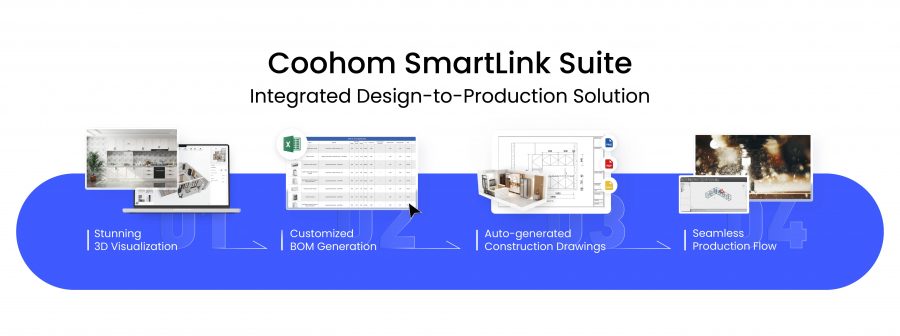

Coohom SmartLink Suite : Rebuilding the Connection Between Design and Manufacturing for Custom Furniture Brands

The custom furniture industry has long grappled with persistent challenges such as information silos between design and production teams, cumbersome order workflows, and significant material waste, all of which hinder efficiency and scalable growth. Coohom SmartLink Suite was developed as an integrated design-to-production solution to directly address these core pain points. It establishes seamless digital connectivity from the initial design concept all the way through to manufacturing, providing comprehensive support across diverse business models.

End-to-End Digital Workflow with Real-Time Visualization

The SmartLink Suite streamlines your operations with key features that elevate performance:

- Unified Catalog Management: Experience simplified data management and significantly reduced errors with a single, comprehensive catalog. This contrasts sharply with traditional CAM approaches that often rely on multiple, disparate catalogs, leading to increased complexity.

- Integrated Design Validation: Validate designs directly within the platform, accelerating approval processes. Unlike traditional methods that frequently necessitate external tools for validation, SmartLink Suite keeps everything in one place, speeding up production.

- Real-Time Model Synchronization: Ensure consistent data across all teams with automated updates. This eliminates the delays and errors often associated with the manual syncing required by traditional CAM systems.

- Fast Cloud Deployment: Benefit from rapid setup and minimal training thanks to our cloud-based SaaS solution. This is a distinct advantage over traditional CAM software, which typically demands on-site installation and prolonged onboarding periods.

Connecting with Clients: Real Interest, Real Needs

Throughout the exhibition, Coohom engaged with dozens of furniture manufacturers, integrators, and design-tech teams from Europe, APAC, and Latin America. While marking its European debut, SmartLink Suite garnered significant interest from a strong contingent of APAC customers, further cementing Coohom’s relationships in the region, alongside new connections made with European and Latin American partners. Many expressed genuine excitement about SmartLink Suite’s potential to eliminate redundant steps, significantly reduce material waste, and drastically cut lead times.

Attendees frequently shared how a unified platform could transform their operations. For instance, one furniture manufacturer noted, “The ability to handle intricate designs without sacrificing speed is a game-changer. It’s not just software; it’s a competitive edge.” This sentiment was echoed by many, highlighting the industry’s strong demand for solutions that drive both innovation and cost savings.

Ecosystem Dialogue: Insights from Our Global Partners

Beyond client meetings, LIGNA was also a valuable platform to engage with ecosystem partners—CNC machinery vendors, and MES providers. Through in-depth discussions, we gained valuable insights:

- System Compatibility is key: Manufacturers are looking for platforms that can plug into existing ecosystems.

- Visual precision matters: Designers want more than speed—they want accuracy that translates to the workshop.

- Cloud-first is now mainstream: SaaS-based manufacturing tools are now the default choice for modern enterprises.

Step into the Future of Custom Furniture Manufacturing with Coohom SmartLink Suite

Discover how Coohom SmartLink Suite can revolutionize your workflows:

- Contact us to Schedule a Consultation and Discover Coohom SmartLink Suite’s Potential

- Connect with us on LinkedIn

- Email our sales team: Sales@coohom.com

The launch of SmartLink at LIGNA 2025 marks another milestone in Coohom’s mission to empower smart manufacturing. We’re excited to build deeper partnerships with global clients and ecosystem players to create more agile, intelligent, and connected production workflows.